Lithium Metal Batteries - KAIST breakthrough

Lithium metal battery breakthrough - reducing SEI dendrite formation

Difference Between Lithium-Ion and Lithium-Metal Batteries

The article discusses both types in the context of this breakthrough:

Lithium-ion batteries are the current standard in EVs. They use graphite anodes and have been limited to around 372 miles of range with fast charging capabilities that degrade over time.

Lithium-metal batteries use a lithium metal anode instead of graphite, which allows for significantly higher energy density. This means they can store more energy in the same space, enabling longer range (the new battery achieves 500 miles). However, they've faced a major challenge: dendrite formation during charging, which has prevented their widespread adoption until now.

The key advantage of lithium-metal is higher energy capacity, but the dendrite problem has historically made them impractical for EVs.

The Cohesion Theory Explained

The KAIST researchers discovered that dendrite formation is caused by non-uniform interfacial cohesion on the lithium metal surface. Here's what that means:

When a battery charges, lithium ions need to deposit evenly across the anode surface. However, the cohesion (the attractive forces between molecules) on the lithium metal surface is uneven, creating stronger and weaker spots. The lithium ions tend to deposit more heavily at certain points rather than spreading uniformly, which creates the branching, crystalline dendrites.

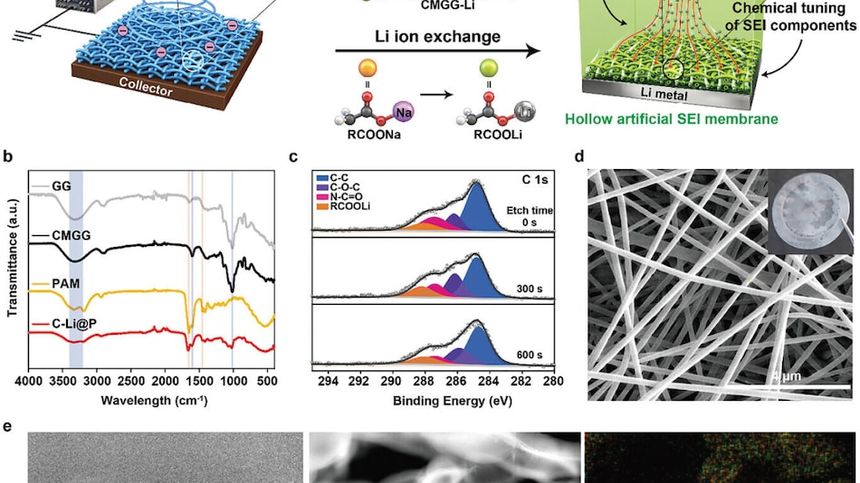

The breakthrough solution is a cohesion-inhibiting liquid electrolyte that chemically prevents this uneven bonding. By reducing the cohesion forces that cause clustering, the electrolyte helps lithium ions deposit more evenly across the entire anode surface during charging. This prevents dendrites from forming, allowing for fast charging (12 minutes to go from 5% to 70%) while maintaining the battery's performance over 350+ cycles.

How Lithium-Metal Batteries Work

Basic Operation:

In any lithium battery, charging and discharging involves lithium ions moving between two electrodes through an electrolyte:

- During discharge (powering your device): Lithium ions flow from the anode (negative electrode) through the electrolyte to the cathode (positive electrode), generating electricity

- During charging: The process reverses - lithium ions move back from the cathode to the anode

The Lithium-Metal Difference:

Lithium-ion batteries use a graphite anode where lithium ions nestle between layers of carbon atoms in a process called "intercalation." Think of it like sliding cards between the pages of a book - the lithium ions slot into predetermined spaces in the graphite structure.

Lithium-metal batteries use pure metallic lithium as the anode. During charging, lithium ions don't just slot into existing spaces - they actually plate directly onto the metal surface, forming new layers of lithium metal. This is called "electrodeposition."

Why Lithium-Metal is Superior (in theory):

Pure lithium metal is the ultimate anode material because:

- Highest theoretical energy density: Lithium is the lightest metal and has the highest electrochemical potential

- 10x higher capacity than graphite per unit weight

- No "host" material needed: Graphite anodes waste space holding the carbon structure; lithium-metal uses pure active material

- This translates to batteries that could be significantly lighter and longer-lasting

Why We Don't See Lithium-Metal Products

Despite being theoretically superior for decades, lithium-metal batteries have been largely absent from consumer products due to several critical problems:

1. The Dendrite Problem (The Main Killer)

This is the issue the KAIST research addresses:

- When lithium ions plate onto the metal surface during charging, they don't deposit uniformly

- They form spiky, tree-like structures called dendrites that grow outward from the anode

- These dendrites can:

- Pierce the separator between anode and cathode, causing a short circuit

- Break off and float in the electrolyte, reducing capacity

- Create hotspots that can trigger thermal runaway (fires/explosions)

- The problem gets exponentially worse with fast charging, as rapid ion deposition creates even more uneven plating

2. Safety Concerns

- Lithium metal is highly reactive - it can catch fire when exposed to air or water

- Internal short circuits from dendrites can cause catastrophic battery failure

- The 1980s saw several lithium-metal battery fires in consumer devices, leading to their effective ban

3. Limited Cycle Life

- Each charge-discharge cycle causes:

- Some lithium to become "dead" (electrochemically inactive)

- Volume expansion and contraction of the anode (lithium metal swells as it plates)

- Formation of a crusty layer called the solid-electrolyte interphase (SEI) that consumes lithium

- Traditional lithium-metal batteries might only last 50-100 cycles vs. 1,000+ for lithium-ion

4. Manufacturing Challenges

- Lithium metal must be handled in completely dry, oxygen-free environments

- Much more expensive to produce than graphite anodes

- Quality control is extremely difficult due to sensitivity

Current Limited Use:

The only lithium-metal batteries you might encounter are:

- Primary (non-rechargeable) batteries in watches, medical devices, and military equipment - these avoid the dendrite problem by never recharging

- Experimental solid-state batteries where the solid electrolyte can physically block dendrite growth

- Research prototypes testing various dendrite-suppression strategies

Why This KAIST Breakthrough Matters

The cohesion-inhibiting electrolyte potentially solves the decades-old dendrite problem by ensuring even lithium deposition. If it proves commercially viable, it could finally unlock:

- 500+ mile EV ranges with 12-minute charging

- Smartphones lasting days on a single charge

- Lightweight batteries for aircraft and drones

However, moving from laboratory success to mass production typically takes 5-10 years, so we shouldn't expect lithium-metal EVs in showrooms immediately.